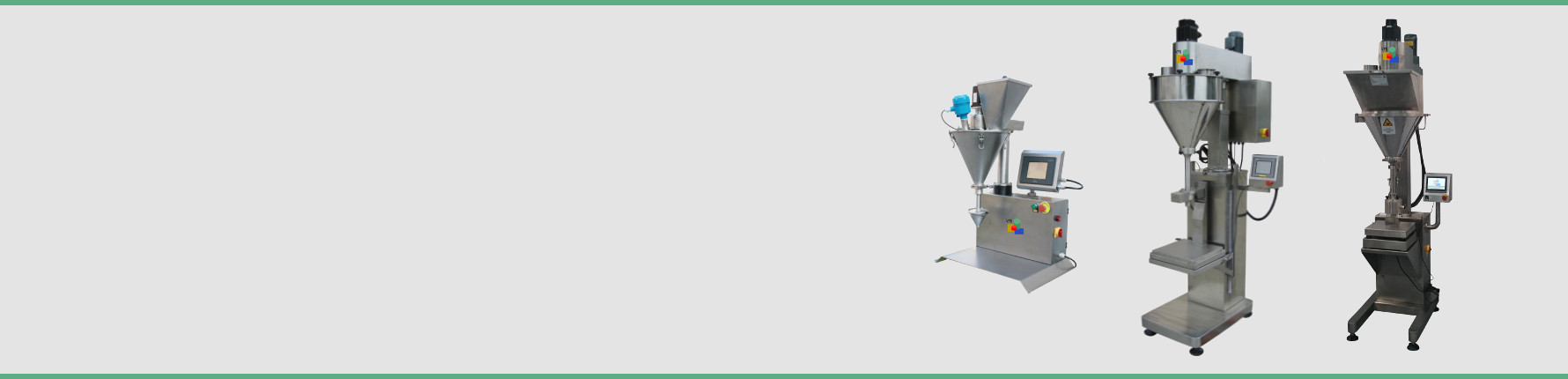

Auger filler full-automatic

Simple and high performance auger filler with or without an integrated weighing system. Operation is simple via a colored touch screen without compromise. Overall design of the auger is extremely compact, service-and maintenance-friendly and easy to clean. The auger comply with all applicable requirements and regulations for machinery and equipment for use in the pharmaceutical & chemical industry and in food industries.

Auger filler SD 100/03

- Rough & fine dosing by volumetric dosing

- Process control by tendency control via downstream check weigher

or manual via platform scale - Volumetric dosing with auto adjustment

- Powerful servo motors for dosing (bis 3 kW, 6000 rpm)

- Needle sieve at the end of the dosing tube for floury powder

- Manifold solution for free flow products like flaps, bevel closure, fish mouth…

- Colored touch screen 7“

- Extensive statistics with individual weight evidence

- User administration 21 CFR part 11

- Discharge function

- Complete stainless steel design

- Auger screw with servomotor

- Made by GMP Design

- Product hopper slewable for easy cleaning and discharge

- Height adjuster 200mm

- Easy handling, easy cleaning

- Special auger pipes made for different types of VFFS machines

- Display cabinet with 3m long cable

- Different main cabinets available for customize mounting

- More special designs available

Auger filler SDW 102 DT/BD speed plus

- Rough & fine dosing by volumetric dosing

- Process control by tendency control via integrated check weighing

after dosing or by downstream check weigher - Volumetric dosing with auto adjustment

- Vibrator below the metering station

- Powerful servo motors for dosing (bis 3 kW, 6000 rpm)

- Needle sieve at the end of the dosing tube for floury powder

- Manifold solution for free flow products like flaps, bevel closure, fish mouth…

- Colored touch screen 7“

- Extensive statistics with individual weight evidence

- User administration 21 CFR part 11

- Discharge function

- Complete stainless steel design

- Auger screw with servomotor

- Made by GMP Design

- Product hopper slewable for easy cleaning and discharge

- Height adjuster 200mm

- Easy handling, easy cleaning

- Integrated star wheel

- Integrated conveyors with covering

- Reject system for plus-& minus weights

- Brushless motors

- More special designs available

- Output upto 35 glasses/jars per minute

Auger filler SDW 102 DT/BD - Clean Design -

- Clean design – fully enclosed metering station

- Rough & fine dosing by volumetric dosing

- Process control by tendency control via integrated check weighing

after dosing or by downstream check weigher - Volumetric dosing with auto adjustment

- Vibrator below the metering station

- Powerful servo motors for dosing (bis 3 kW, 6000 rpm)

- Needle sieve at the end of the dosing tube for floury powder

- Manifold solution for free flow products like flaps, bevel closure, fish mouth…

- Colored touch screen 7“

- Extensive statistics with individual weight evidence

- User administration 21 CFR part 11

- Discharge function

- Complete stainless steel design

- Auger screw with servomotor

- Made by GMP Design

- Product hopper slewable for easy cleaning and discharge

- Height adjuster 200mm

- Easy handling, easy cleaning

- Integrated star wheel

- Integrated conveyors with covering

- Reject system for plus-& minus weights

- Brushless motors

- More special designs available

- Output upto 35 glasses/jars per minute

Auger filler SDW 200 BD speed - Clean Design -

- Clean design – fully enclosed metering station

- Rough dosing, fine dosing direct controlled of rough dosing

with integrate final check weighing and tendency control - Volumetric dosing with auto adjustment

- Vibrator below the metering station

- Powerful servo motors for dosing (bis 3 kW, 6000 rpm)

- Needle sieve at the end of the dosing tube for floury powder

- Manifold solution for free flow products like flaps, bevel closure, fish mouth…

- Colored touch screen 7“

- Extensive statistics with individual weight evidence

- User administration 21 CFR part 11

- Discharge function

- Complete stainless steel design

- Auger screw with servomotor

- Made by GMP Design

- Product hopper slewable for easy cleaning and discharge

- Height adjuster 200mm

- Easy handling, easy cleaning

- Integrated conveyors with covering

- Reject system for plus-& minus weights

- Brushless motors

- More special designs available

- Output upto 55 glasses/jars per minute

SDW 400 BD speed - Clean Design -

- SDW 400 Output up to 100 glasses/jars per minute

- Twice rough dosing, twice fine dosing direct controlled of rough dosing with integrate final check weighing and tendency control

- Integrated infeed and outfeed conveyors with ditributors

Auger filler SDW 100 twin speed plus

- Rough & fine dosing by volumetric dosing

- Process control by tendency control via downstream

check weigher or manual via platform scale - Volumetric dosing with auto adjustment

- Vibrator below the metering station

- Powerful servo motors for dosing (bis 3 kW, 6000 rpm)

- Needle sieve at the end of the dosing tube for floury powder

- Manifold solution for free flow products like flaps, bevel closure, fish mouth…

- Colored touch screen 7“

- Extensive statistics with individual weight evidence

- User administration 21 CFR part 11

- Discharge function

- Complete stainless steel design

- Auger screw with servomotor

- Made by GMP Design

- Product hopper slewable for easy cleaning and discharge

- Height adjuster 200mm

- Easy handling, easy cleaning

- Integrated conveyors with covering

- Reject system for plus-& minus weights

- Brushless motors

- More special designs available

- Output up to 40 glasses/jars per minute