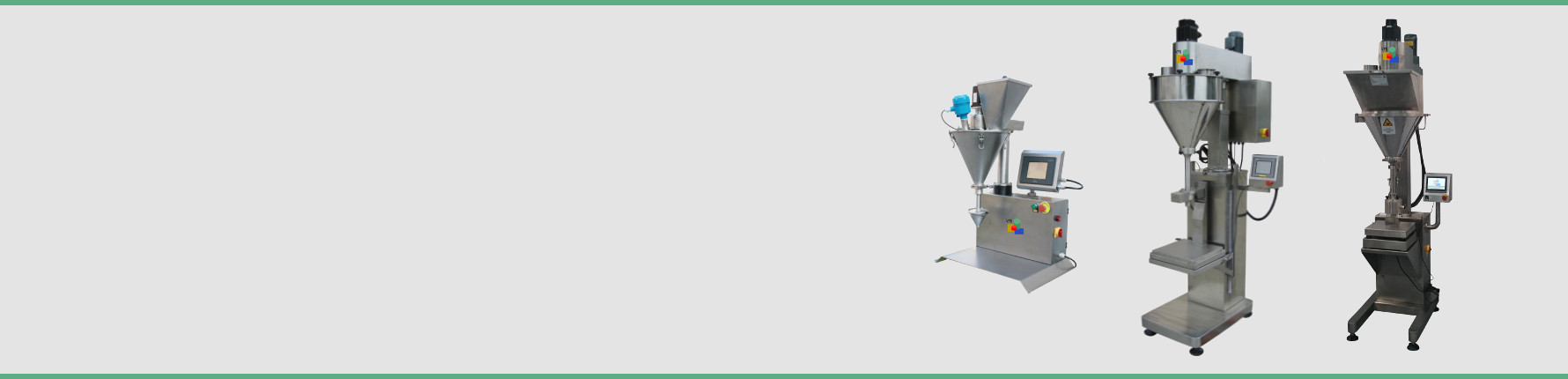

Auger filler semi-automatic

Simple and high performance auger filler with or without an integrated weighing system. Operation is simple via a colored touch screen without compromise. Overall design of the auger is extremely compact, service-and maintenance-friendly and easy to clean. The auger comply with all applicable requirements and regulations for machinery and equipment for use in the pharmaceutical & chemical industry and in food industries.

Special highlight of the auger filler line SDW 100/105

With our modified weighing technology finally possible:

- Weighing and vibrating simultaneous within the dosing process

The weighing platform is firmly attached to the vibrating plate - Pantented technology of the modified weighing unit especially for industrial use

- ATEX zones 1, 2,

- ATEX zones 20, 21 or 22

- Single type approval test of official verification (standard)

Auger filler SD Desktop 05

- Color touch screen 5.7 "

- Complete stainless steel design

- Needle sieve at the end of the dosing tube for floury powder

- Centrifugal disc with free flow device for a free-flowing Product (for crystalline products)

- Standard dosage range from 3-80 g (max 100g depending on the bulk density)

- Swirled auger screw with servo motor

- Dosing unit easy to clean and to empty, discharge function

- Removable hopper with safety sensor

- GMP design

- Gear drive with brushless motors

More pictures from the auger filler SD05 Desktop

Auger filler SDW HW 100 LT plus

- Rough & fine dosing by gravimetric with check weighing

- Volumetric dosing with auto adjustment

- With integrated weighing platform direct read adjustment of dosing process

- Gravimetric and volumetric dosing

- Colored touch screen 7“

- Extensive statistics with individual weight evidence

- User administration 21 CFR part 11

- Discharge function

- Complete stainless steel design

- Auger screw with servomotor

- Needle sieve at the end of the dosing tube for floury powder

- Centrifugal disc with free flow device for a free-flowing Product (for crystalline products)

- Made by GMP Design

- Product hopper slewable for easy cleaning and discharge

- Integrated lifting device to dipping the auger screw into the sack

- Height adjuster 200mm

- Easy handling, easy cleaning

- Bag clamp for bags and sacks

- Standard dosing range from 3 kg - 30 kg or 5 kg to 50 kg

- More special designs available

Auger filler SDW 100 / 105

- Rough & fine dosing by gravimetric with check weighing

- Volumetric dosing with auto adjustment

- With integrated weighing platform direct read adjustment of dosing process

- Gravimetric and volumetric dosing

- Colored touch screen 7“

- Extensive statistics with individual weight evidence

- User administration 21 CFR part 11

- Discharge function

- Complete stainless steel design

- Auger screw with servomotor

- Needle sieve at the end of the dosing tube for floury powder

- Centrifugal disc with free flow device for a free-flowing Product (for crystalline products)

- Made by GMP Design

- Product hopper slewable for easy cleaning and discharge

- Integrated vibration unit

- Special function „weighing and vibrating simultaneous”

- Height adjuster 200 mm

- Easy handling, easy cleaning

- Bag clamp and bag holders for bags

- Holders for tins, cans and bulks

- Weight range 1g – 5.000g

- More special designs available