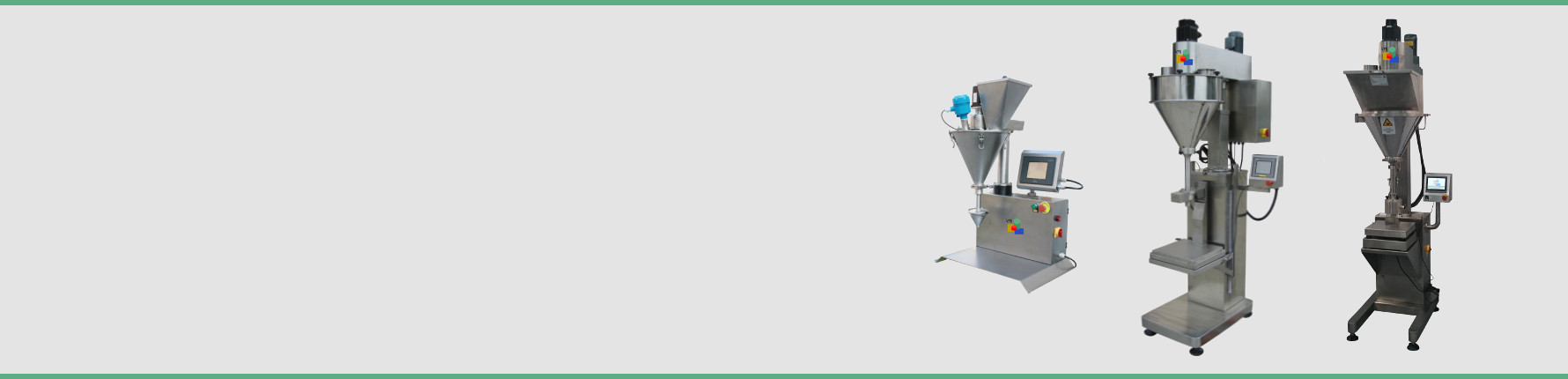

Linear weigh filling machines

Linear weigh filling machine for the metering and dosing of pharmaceutical, chemical or technical products as well as for filling food products or food supplements.

Linear weigh filling machine series AW100

Our single- , twin and multiple track (up to 10-fold) AW100 series linear weigh filling machine consist of two cascades each, as well as the product flap, product sensor and split load pan per filling track. Operation is uncompromisingly easy via a touch screen. All product data and parameters are processed in just one screen window and are always available. The filling scales are available in versions completely stainless steel (1.4301 optional 1.4571).

The product-touching parts are basically made of stainless steel. Product transport takes place via channels with vibratory drives (magnetic resonance, imbalance motors) or by means of belts with motors (servo, stepper, gearbox).

Linear weigh filling machine AW 100

The most important customer benefits of the linear weigh filling machines

- Simple operation with just one single parameter input "target weight"

- Fast product changeover, easy cleaning

- GMP and HCPPA compliant versions

- Great handling

- Large weighing range

- Finishes in stainless steel

- ATEX compliant versions

- Operation via touch screen

- External target weight preset possible

- Printer control, freely configurable

- Various interface modules

- Profibus module RS 232, RS 485

- Ethernet module

- I / O module up to 32 inputs and Outputs, freely selectable

- Realization of customer requirements

Linear weigh filling machies series AW20

Each of our Twin linear weigh filling machines of the AW20 series consists of a vibrating track with product flap and a split load pan with stepper motor. The product storage hopper is equipped with a product sensor. The vibrating troughs and load pan are provided with a cover. Operation is uncompromisingly easy via a touch screen. All product data and parameters are processed in just one screen window and are always available. The execution of the twin linear weigh filling machines is completely made of stainless steel (1.4301).

Our filling weighing controllers operate with state - of - the - art microprocessor technology. The controllers are designed in a range-oriented manner, with high demands on the accuracy and the greatest possible performance. The filling weighing controllers of all series are target weight oriented and control the vibration drives with a speed offset. Furthermore, the filling weighing controls of all series are characterized by simple operation and handling. All menu steps and sub-items are displayed in the clear text, as well as error messages.

In principle, all filling scales for preparation and synchronization are prepared for a packaging machine. The filling scale sends a finished message after reaching the desired weight. The shedding is triggered by the incoming signal of the hose bag machine - signal identification "packaging available". After the discharge, the filling weighing machine starts automatically, sends the finished message and waits for the "Packaging present" input. Error message goes overweight with signal to the packaging machine.

Microwaage für Granulate Wiegebereich 1g - 10g